Customer support provided by the NICE CARBON Technology is comprehensive and complete in all aspects of the project including project, design, appliance, testing, manufacturing and sustained product analysis. In the laminating design of composite products, we choose the combination of various fiber weaving methods to optimize and present the best layering design according to the stress of the products. In addition, the multi-axial carbon fiber fabric is selected because of its superior advantages of flexible weaving, efficient layering and layering accuracy compared with uniaxial fiber fabric.

Uniaxial carbon fiber fabric (0°)

Uniaxial carbon fiber fabric is a kind of cloth with plenty of carbon fiber yarns in one direction (usually in the longitudinal direction) and slight and usually thin fiber yarns in the other direction. In fact, all the strength of the fabric is loaded in the first direction.

Biaxial carbon fiber fabric (0°/90°,±45°)

Plain weave

Plain weave:A single warp yarn is arranged up and down in a sequence of intersecting weft yarn. Plain weave is of uniform symmetry, complete structure, optimal fiber stability and reasonable porosity. However, plain weave fabric has a very high folding rate, which reduces the mechanical strength of the fiber by approximately 15%.

Twill weave

Twill weave:Single or multiple warp yarns and two or more weft yarns are arranged in an orderly up-and-down cross arrangement. The surface has a diagonal grid or twill texture. Twill weave can retain the strength and modulus of carbon fibers to the maximum extent.

Satin weave

Satin weave:Satin weave has individual and discontinuous warp interlacing points (or weft interlacing points) in a regular uniform distribution within the organization cycle. Such weave form is defined as satin weave. It is characterized by long floating threads of warp yarns (or weft yarns) and few interlacing points. Despite of forming diagonals, the yarns are not continuous and the spacing distance is regular and uniform. Warp yarns and weft yarns of satin weave fabrics are interlaced once at least every three threads. Therefore, the weave structure makes a higher density and thicker fabrics. Satin weave fabric is of smooth and even surface, soft texture, rich luster or slight grain. Common satin weave fabrics are inclusive of four satin weaves, five satin weaves and eight satin weaves.

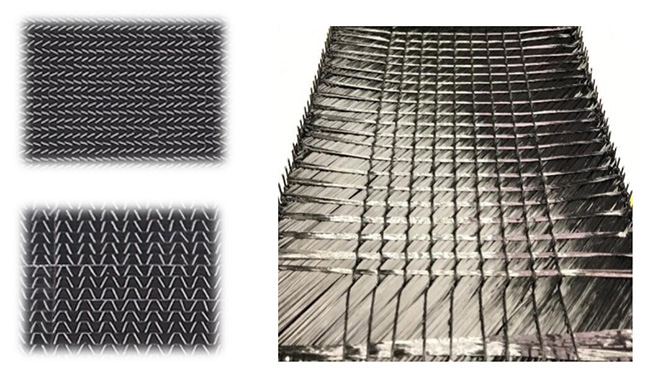

Tri-axial carbon fiber fabric (0°/±45°)

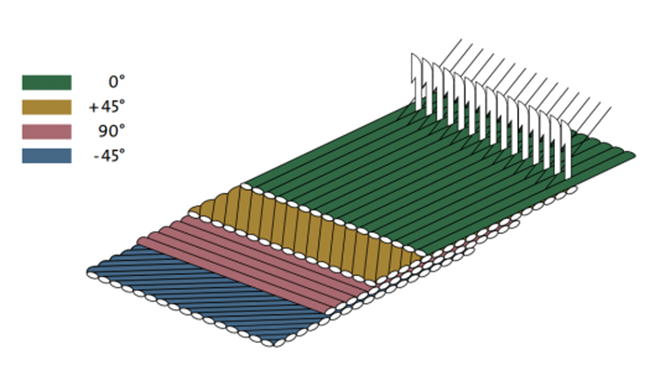

Quadaxial cloth (0°/-45°/90°/+45°)

Multiaxial warp knitting technology is a textile method comprising woven and knitted techniques, and the woven fabric obtained by this technique is generally referred to as a non-bending fabric. This fabric is very unique, while the non-bent yarns are oriented at any angle between 0°, 90° and ±30° to ±60°.